Hazardous materials are everywhere—from industrial chemical plants to janitorial closets. If it’s flammable, toxic, corrosive, or reactive, it needs a label that tells you what you're dealing with. That’s where GHS hazard labels come in. The Globally Harmonized System (GHS) was created to put everyone on the same page when it comes to chemical hazards, no matter where in the world you’re working.

Before GHS, labeling rules varied widely depending on the country or even the industry. Now, GHS labels provide a unified way to communicate risks and responsibilities clearly and consistently. They’re not just stickers; they’re a legally required safety tool that helps prevent accidents, injuries, and costly fines. Whether you’re handling bleach or benzene, GHS labels give workers the visual and written clues they need to stay safe.

In this guide, we’ll break down everything you should know about GHS-compliant hazardous material labels—including who needs them, what goes on them, where to source them, and how to use them properly. If you're here to stay compliant, prevent mistakes, and simplify your hazard communication workflow, you're in the right place. For quick access to visual examples of compliant labeling, check out our hazard warning decals.

What Are GHS Hazard Labels?

GHS hazard labels are the standardized tags or stickers placed on containers of chemicals to communicate the type and level of hazard they pose. GHS stands for the Globally Harmonized System of Classification and Labeling of Chemicals. It’s a worldwide framework developed by the United Nations to eliminate the confusion caused by differing national and regional label systems.

Before GHS came along, chemical labeling was kind of the Wild West—different countries (and sometimes even different companies) followed their own rules. You’d find inconsistent symbols, ambiguous language, or missing hazard info entirely. GHS changed that. Now, hazard labels follow a shared format—same signal words, consistent pictograms, clear hazard and precautionary statements. The result? Workers can instantly understand the danger, whether they’re in Texas, Tokyo, or Toronto.

Here’s what that really means: if you're handling or distributing chemicals, whether you're a manufacturer, importer, employer, or warehouse manager, you absolutely need to follow GHS standards. In the U.S., OSHA aligned its Hazard Communication Standard with GHS in 2012—so it's not just a good safety move, it's the law.

So, what’s on these labels? Each GHS-compliant tag includes a product identifier, signal word ("Danger" or "Warning"), hazard and precautionary statements, the universal pictograms, and supplier info. If you're looking for an example or need ready-to-go decals, hazard warning decals offer a quick, compliant way to get started.

Bottom line: GHS hazard labels create a common language for chemical safety. They're not just stickers—they're lifesavers in bold, red diamonds.

Why GHS Labels Matter in the Workplace

GHS labels aren’t just stickers on a bottle—they're your frontline defense against chemical accidents. Whether you’re in a lab, warehouse, or construction zone, a clear, standardized label can make the difference between a regular Monday and an emergency call.

Let’s cut to it. When chemicals are handled daily, there’s no room for ambiguity. GHS labels spell things out with clear pictograms, signal words, and hazard statements so that anyone—from new hires to seasoned pros—knows what they’re dealing with at a glance. That instant recognition helps prevent spills, burns, inhalation accidents, and the usual roster of workplace hazards.

But there’s more than just common sense at work here—there’s also the law. OSHA adopted the GHS framework under the Hazard Communication Standard (HCS), which means U.S. employers are legally required to use the system. If you’re distributing hazardous materials or managing a facility that stores them, failing to comply can result in fines or worse.

Aside from the legal side, GHS labels are critical pieces in the broader hazard communication puzzle. They work hand in hand with Safety Data Sheets (SDS) and safety signage to create a reliable system of awareness. For example, pairing correctly labeled containers with safety warning signs around the work zone enhances visibility and keeps everyone on the same page—especially in dynamic, high-activity environments.

Bottom line? GHS labels help your team stay safe, keep your operation compliant, and bring order to the chaos that sometimes comes with handling hazardous materials. They’re not optional—they’re essential.

Key Elements of a GHS-Compliant Label

So, what makes a label “GHS compliant”? It’s more than just slapping a skull-and-crossbones on a jug and calling it a day. A proper GHS label includes several critical elements that work together to tell workers exactly what they're dealing with—clearly, quickly, and without interpretation gymnastics.

Let’s break it down:

1. Product Identifier

This is the formal name or number used to identify the substance or mixture. It has to match exactly what’s on the Safety Data Sheet (SDS). Think chemical name, batch number, or code—whatever ensures there's no confusion about what's inside the container.

2. Signal Word

Just one word, but a powerful one. Either “Danger” or “Warning.”

- “Danger” is for high-severity hazards.

- “Warning” signals lower-level threats.

Simple system. No fluff.

3. Hazard Statements

These describe the nature of the hazard in plain terms—no vague legalese. Examples?

- “Causes serious eye irritation.”

- “Highly flammable liquid and vapor.”

Each statement is specific to the chemical and is pulled directly from GHS classification guidelines.

4. Precautionary Statements

This is where you spell out how to stay safe and what to do if things go sideways.

- Prevention: “Do not breathe dust/fume/gas/mist/vapors/spray.”

- Emergency Response: “IF SWALLOWED: Call a poison center or doctor.”

- Storage and Disposal: “Store locked up. Dispose of contents in accordance with local regulations.”

Clear steps make for fewer accidents.

5. Supplier Identification

You need to list who’s responsible for the chemical. That includes:

- Name of the company

- Address

- Phone number

This matters when something goes wrong and someone needs to get answers—fast.

6. Pictograms

These are the instantly recognizable symbols framed in red diamonds that visually alert workers to specific hazards. There are nine total, but OSHA enforces eight in the U.S.

Here’s a snapshot:

- Flame: Flammable or combustible (alcohol, acetone)

- Skull and Crossbones: Acute toxicity (can be fatal)

- Corrosion: Can cause skin burns or eye damage

- Exclamation Mark: Irritant or less severe toxicity

- Gas Cylinder: Gases under pressure

- Flame Over Circle: Oxidizer

- Exploding Bomb: Explosives or unstable materials

- Health Hazard: Carcinogen, reproductive toxicity

Want a quick visual reference? Check out our Hazard Warning Decals collection to see real-world examples of these pictograms in action.

Putting it all together, a GHS-compliant label is your first line of defense. It's not there to look official—it's there to keep people from getting hurt. Keep it accurate, keep it consistent, and make sure everyone knows how to read it. Straightforward safety wins every time.

Understanding GHS Labeling Requirements

Knowing when and how to label hazardous materials isn’t optional—it’s essential. GHS labeling requirements are standardized for a reason: they eliminate guesswork and help prevent serious incidents. Here’s what you need to know to stay on track.

When Labels Are Required

GHS labels are required any time a hazardous chemical is in use, storage, or transit. If it’s in a container and contains a classified chemical, it needs a label—period. That includes bottles, bags, drums, barrels, tanks, and even smaller vials if they’re in active use. Secondary containers used for batched or transferred chemicals also need compliant labels, especially if they’ll be handled by more than one person or stored for any length of time.

One exception? Immediate-use containers—those kept under direct control and used up during the work shift—may not need full GHS labels. But play it safe: clear, visible markings are always a smart move.

Label Size and Placement

There’s no one-size-fits-all rule for label dimensions, but they need to be legible, durable, and prominently displayed. If someone can't read it easily from a reasonable working distance or it’s smudged beyond recognition, it’s not doing its job. As a quick reference, labels should be large enough to hold all required elements—signal word, pictograms, hazard and precautionary statements—without cramming them in like fine print.

For oversized containers, make sure the GHS label is placed where it's always visible during normal operations. Don’t slap it under a spout or behind a handle where it’ll get hidden during use.

Updating Labels: Not Just a “Once and Done”

Whenever the chemical’s hazard classification changes, or the Safety Data Sheet is updated with new information, GHS labels must be revised accordingly. You'll also need to update labels if the product formulation changes, the manufacturer’s contact info is updated, or if any precautionary wording is altered per regulatory updates. Periodic audits of labeling compliance are good practice—and they can save you from fines, liability, or worse.

Labels, SDS, and Chemical Safety Signs—Working Together

Think of GHS labels as the front lines of chemical safety. They alert and inform. But they’re part of a bigger system that includes Safety Data Sheets (SDS) and safety signage throughout the workplace. Each chemical’s SDS offers the in-depth detail behind the label: what to do in an emergency, how to store the material, and what kind of PPE is required.

To reinforce these efforts, make sure your work areas feature appropriate chemical safety signs and labels. These act as static reminders of hazards, even when the original chemical container isn’t visible. Safety decals placed on cabinet doors, storage tanks, or lab walls serve as a second line of defense.

Bottom line: a GHS label by itself isn’t enough. But when combined with clear signage and up-to-date SDS documentation, it becomes part of a seamless safety net that catches small mistakes before they become major accidents.

5. Hazardous Material Signage vs. GHS Labels

Let’s clear up a common source of confusion: hazardous material signage is not the same as GHS container labels. They might seem interchangeable if you're not deep in the safety world, but they serve distinct purposes—and mixing them up can lead to fines, injuries, or worse.

GHS labels are product-specific warnings. They're applied directly to chemical containers like drums, bottles, or tanks and tell you exactly what's inside. They include details like the chemical name, hazard pictograms, and precautionary steps. They're designed for close-up reading—meant for the person handling the product.

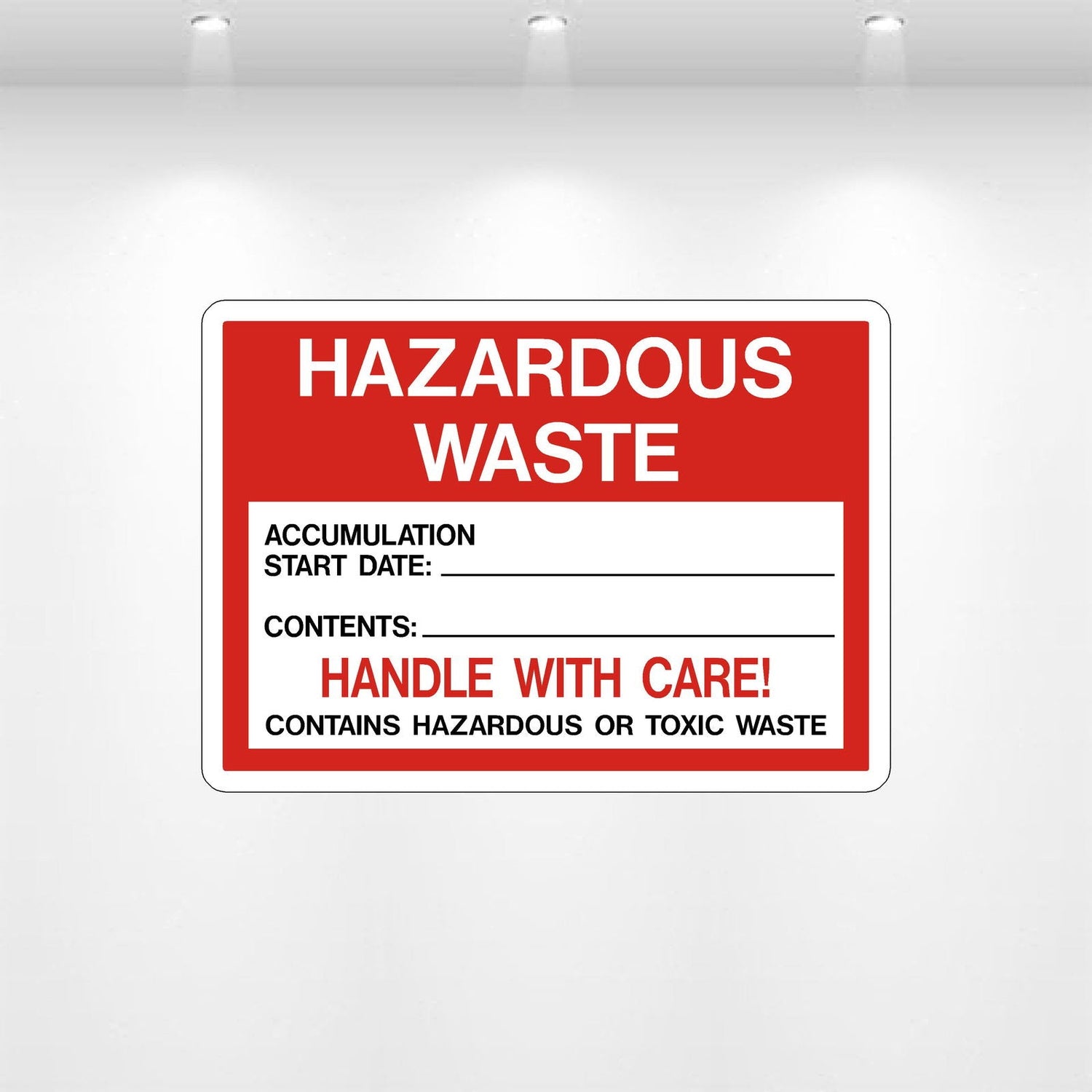

Hazardous material signage, on the other hand, is location-based. Think large wall signs in a warehouse that warn about flammable materials in the area, or placards on transport trucks showing that corrosive materials are on board. These signs provide a quick, visible alert to anyone walking by, even from a distance.

So where do you use each?

- GHS labels go on every container of a hazardous chemical, no matter the size.

- Hazardous signage gets posted in places where chemicals are stored, handled, or transported.

Examples:

- In a factory, you might have a GHS label on a barrel of sulfuric acid and, at the entrance to that storage room, a wall sign that warns of corrosive hazards in the immediate environment.

- In transit, each sealed drum of chemical must be labeled with GHS info, while the truck transporting them must display hazardous material signage visible to DOT inspectors and emergency responders.

If you're building out your safety system, don’t overlook the need for both label types. For clearly marked zones and highly visible warnings, check out our Safety Labels and Signs Collection. It includes everything from flammable signage to high-voltage decals that keep your worksite compliant and your workers informed.

Applying GHS Labels in Real-World Settings

Labeling hazardous materials in theory is one thing. Doing it in the messy, fast-moving pace of a real-world worksite? That’s where the rubber meets the road—and unfortunately, it’s also where plenty of safety missteps start.

Let’s break down a few of the most common labeling scenarios and how to get them right.

Small Containers: Don’t Skip the Details

Containers under 100 ml or even as small as test tubes still need labels. Just because it’s small doesn’t mean the contents are less dangerous. For tiny containers, OSHA allows simplified labels in some cases, but at a minimum, you must include:

- Product identifier

- Appropriate pictogram(s)

- Signal word (like “Warning”)

If space is tight, use secondary packaging or tags that reference the full label and make sure the Safety Data Sheet (SDS) is easily accessible to workers. Pro tip: pre-print small-size hazard warning decals or use labels made specifically for narrow cylinders or vials. Slapping on a piece of masking tape and a Sharpie won’t cut it.

Mixed Contents or Repackaged Materials

If you’re mixing chemicals or transferring them into smaller containers for any reason, you become the “manufacturer” in the eyes of OSHA. That means you're responsible for full, accurate labeling. You need to:

- Generate an appropriate GHS-compliant label

- Include the correct hazard pictograms and statements

- Keep SDS available for the new mixture or repackaged material

It’s not just about liability—it’s about ensuring everyone down the line understands exactly what they’re handling.

Legibility and Durability: Labels That Last

Labels fade, peel, smudge, or fall off. That’s not just an inconvenience—it’s a safety hazard. If a worker can’t read a label, they can’t protect themselves from what’s inside.

Here’s what to look for:

- Use waterproof, smudge-resistant, and chemical-resistant materials

- Go with UV-resistant inks or coatings for outdoor settings

- Choose adhesive backing that won’t give out in high-humidity or high-traffic zones

For workplaces facing harsh environments, investing in industrial-grade labels from a dedicated safety label supplier can save you from having to reapply or relabel constantly.

Bottom line: a GHS label is only useful if it stays on, stays legible, and says what it’s supposed to. Get those three things right, and you’re already ahead of most chemical handling operations out there.

Common Questions About GHS Labels

GHS labels aren’t always intuitive, especially if you’re managing a wide range of chemicals or dealing with compliance across multiple worksites. Let’s clear up some of the most common gray areas and keep your labeling process tight, compliant, and hassle-free.

What do the pictograms mean?

GHS pictograms are visual warnings placed inside red diamonds. Each one quickly tells you what kind of hazard you're facing—flammable, toxic, corrosive, etc. There are nine official symbols recognized by GHS, with only eight required under OSHA’s HazCom standard in the U.S. For example, the skull and crossbones means acute toxicity, while the flame over a circle signals an oxidizer. If you’re unsure or want a quick reference, check out our Hazard Warning Decals section to match the right symbol to your chemical type.

When do I need to relabel a container?

Any time the label becomes unreadable, damaged, or if the chemical inside the container changes, you need to relabel. OSHA makes it clear—labels must be legible and accurate at all times. Temporary containers used during one work shift might not need labeling, but if that container lingers beyond the shift or leaves the original handler’s control, slap a compliant label on it.

Can I make my own GHS labels?

Yes, you can create your own—so long as they meet all the required elements: signal word, product identifier, hazard statements, precautionary statements, pictograms, and supplier details. Plenty of companies print their labels in-house using thermal label printers and chemical-resistant stock. Just make sure you're not skipping key information, and test your labels for durability in your operating environment.

Are GHS labels required in the U.S.?

Absolutely. OSHA’s Hazard Communication Standard (HCS), aligned with GHS, mandates that all hazardous chemical containers in the workplace be properly labeled. Whether you're a supplier, manufacturer, or end-user, if you handle hazardous materials, GHS labeling isn’t optional—it’s law.

What happens if I don’t use GHS-compliant labels?

Skipping compliance puts your workers at risk and your business in legal hot water. OSHA citations for HazCom violations rank consistently in the top ten each year. Fines can climb thousands of dollars per offense, and in the event of an incident involving mislabeled chemicals, the consequences escalate fast—workplace injuries, lawsuits, even shutdowns. Using clear, compliant labels and appropriate safety signage is one of the cheapest ways to cover your legal bases and protect your team.

Bottom line? GHS labels aren’t just red tape—they're your frontline defense against avoidable accidents.

8. How to Create and Maintain a GHS Labeling System

Building a reliable GHS labeling system isn’t just about printing labels and slapping them on containers. It’s about creating a process that’s consistent, sustainable, and clearly understood at every level of your operation. Here's how to get it right.

Standardize Your Labeling Process

Start by deciding who’s responsible for labeling, and when it happens. Don’t leave it up to guesswork—spell out roles clearly across departments. Whether it's facilities, EHS teams, or procurement, everyone should know when a label needs to be applied, updated, or replaced. This process should be integrated into your chemical handling workflow from the start, whether you're dealing with bulk chemicals or small-volume containers.

Make sure the same standards apply to every container, every time. Use a centralized system to control label templates so that language, formatting, and pictograms remain consistent. For a hands-on approach, some teams use software to generate GHS-compliant layouts, while others keep a master file of approved label designs.

Train Staff Like It Matters—Because It Does

If employees don’t understand what the labels mean or how to read them, the system falls apart fast. GHS label training should be part of your chemical safety training—yes, even for non-lab roles. Focus on key label elements and how to match them with Safety Data Sheets (SDSs). Include real-world examples to help workers connect the dots between what they see on a label and how they should respond.

And don’t make it a one-off session. Revisit training when new chemicals are introduced, when labels change, or when rules are updated. A well-informed team is your first line of defense.

Keep It Updated—Keep It Compliant

Labels don’t last forever. Over time, chemicals get repackaged, hazards get reclassified, and suppliers change. Your labeling system needs to make room for updates. Set up a routine (quarterly or bi-annually works for many operations) to review existing labels. Cross-check them with your current SDSs and confirm the right signal words, hazard statements, and pictograms are in place.

Also, take stock of label condition. If a label is smudged, peeling, or sun-faded, it’s not doing its job. Look for weather- and chemical-resistant labels made for industrial settings—these types of hazard warning decals are built to last and stay readable even in tough environments.

In short: Don't treat GHS labeling as a one-and-done task. Build a solid system, train your people, and stay on top of maintenance. Do that, and you’ll stay compliant—and protect your crew at the same time.

Avoiding Common Mistakes

Even with the best intentions, GHS labeling errors happen more often than you'd think. And while they might seem minor—a missing word here, or the wrong icon there—they can put people at risk and lead to compliance headaches. Let’s cut through the noise and look at the most common missteps companies make when labeling hazardous materials.

1. Choosing the Wrong Signal Word or Pictogram

The choice between “Danger” and “Warning” isn’t arbitrary. These signal words are based on the severity of the hazard and dictate how workers perceive a chemical’s risk. Slapping on the wrong one can understate a serious threat—or make something look more dangerous than it is. Same goes for pictograms. That flammable symbol? You don’t want it on a bottle of non-combustible cleaner. Always match your signal word and pictogram with the hazard classification listed in the product’s Safety Data Sheet (SDS).

2. Forgetting the Supplier Name

This might look like a small line of text at the bottom of the label, but it matters. GHS requires that the name, address, and contact details of the chemical’s manufacturer or distributor be on every label. Without it, workers and emergency responders have no clue who to contact in a spill or exposure situation. This is a simple detail that tends to slip through the cracks—don’t let it.

3. Labeling the Wrong Area of a Container

Sounds obvious, but it happens. Labels get slapped on the lid, the bottom, or areas that are easily rubbed off. If your label isn’t clearly visible during normal handling and storage, or if it’s placed where it can get easily torn or destroyed, it’s not compliant—and it’s not helpful. Make sure labels are on a flat, clean, visible surface and that they stay put. For high-performance, weather-resistant and chemical-resistant labels are a smart investment.

4. Overcomplicating Language or Using Inconsistent Terms

GHS labels are meant to be clear and concise—not technical documents. You don’t need a wall of text or insider jargon. Stick to standard hazard and precautionary statements. Mixing terminology (e.g., saying “toxic” instead of “acute toxicity”) can confuse workers, especially if multiple chemicals have similar hazards. Consistency is key, both for comprehension and compliance.

Avoiding mistakes isn’t about getting everything perfect—it’s about being intentional and informed. Start with the standards, stay organized, and lean on solid resources to back you up. If in doubt, reference your SDS or check out our full range of OSHA-compliant safety labels and signs to make sure you’re on the right track.

Final Thoughts

GHS-compliant labels aren’t just boxes to check—they’re your first line of defense against confusion, injury, and noncompliance. When you slap a clear, accurate label on a container, you're doing more than following protocol. You're protecting your people, staying on the right side of regulations, and making chemical safety part of the everyday workflow—not an afterthought.

The reality is: working with hazardous materials isn't optional in a lot of industries, but mislabeling or skipping labels is. And that’s where things go south. A good GHS labeling system reduces guesswork, speeds up training, and basically keeps your team from walking into a chemical hazard blind. It’s practical, it’s required, and when done right—it’s seamless.

If you're setting up or updating your labeling process, start with the basics: make sure your labels are readable, durable, and match your Safety Data Sheets. Need compliant labels you can count on? Check out our collection of GHS hazard warning decals built tough for industrial use.

GHS labeling isn't glamorous work. But it’s the groundwork that keeps everyone safer, every shift.