Industrial labels do more than mark equipment. They prevent injuries, guide workers during emergencies, and ensure regulatory compliance. The wrong label can fade, peel, or fall off, especially in tough environments. Choosing the right material makes the difference between staying compliant and facing unresolved safety risks. Whether it’s high heat, harsh cleaners, or rough surfaces, the label has to hold on—and stay readable.

In industrial settings, safety labels aren’t just stickers—they’re part of your frontline defense. The right label warns of active machinery, signals hazardous areas, and reminds staff of critical protocols. But a safety message is only as strong as the material it's printed on. If your label peels off a hot pipe, fades in sunlight, or dissolves under a chemical rinse, it might as well not exist. That leaves workers guessing—and guessing in a high-stakes environment is dangerous.

Choosing a label material isn't just about keeping things looking neat. It's about avoiding accidents, staying OSHA-compliant, and keeping operations running smoothly. A mislabeled pipe could lead to a chemical spill. A missing warning on a high-voltage panel? That’s a liability waiting to happen. And it’s not just the extremes—everyday wear, cleaning products, even a rough concrete wall can destroy a label if it’s not made for the job.

Safety labels serve three vital roles: communication, compliance, and continuity. They tell your crew what’s safe, what’s not, and what to do next. But without the right material behind that message, it all falls apart. Before you print another label, take a minute to ask: will this hold up to heat, UV, solvents, impact—whatever your environment throws at it? Because in the end, it’s not just a label—it’s a safeguard. Choose accordingly.

For areas where visibility is key—think low-light worksites or emergency exits—it’s also smart to consider reflective technology to ensure your message gets seen when it matters most.

What Are Industrial Safety Label Materials?

In industrial settings, a safety label isn't just a sticker—it's a communication tool built for survival. These labels identify hazards, offer instructions, and step in when quick thinking counts. They live on machinery, pipelines, floors, and walls, often in places where the environment is anything but gentle. A true industrial safety label must stay readable and intact even after years of wear and tear.

So what’s under the hood—what are these labels made of?

Common materials for industrial safety labels include vinyl, polyester, polycarbonate, and aluminum. Each has its strengths. Vinyl is flexible, affordable, and works well on curved or uneven surfaces. Polyester handles chemicals better, resists tearing, and lasts longer in harsh conditions. Polycarbonate is ideal for high-impact areas and environments requiring extra toughness. And anodized aluminum is the go-to when you need long-term durability outdoors or in extreme temperatures.

There’s also the matter of how the information is printed. Surface-printed labels have ink or graphics on the top layer, exposed to whatever the environment throws at them. They're typically cheaper but prone to fading or scratching over time. Subsurface-printed labels take a different approach—the print is protected beneath a clear overlaminate or embedded under a plastic or metal surface. This offers extra resilience in settings where abrasion or chemical contact is unavoidable.

If your labels need to be seen clearly in low light or from long distances, consider materials designed with reflective technology. These enhance visibility without adding complex lighting and make a noticeable difference in large industrial spaces or nighttime conditions.

Ultimately, choosing the right material means understanding where the label’s going and what it’ll be up against.

Key Factors When Choosing Safety Label Materials

Here’s the hard truth: even the best-designed safety label is useless if it doesn’t stick—or if it fades, curls, or peels. Choosing the right material isn’t just about cost; it’s about keeping people safe, equipment labeled, and your facility within compliance lines.

Surface Type Is Step One

Start with the base. Is the surface smooth metal? Textured plastic? Pitted concrete? Not every label material plays well with every surface. For example, standard vinyl might perform fine on metal panels, but struggle to bond with rough or oily surfaces. High-adhesion polyester and aluminum-backed decals tend to offer better grip where standard adhesives fail. On curved or irregular surfaces, flexibility matters too—thinner films can conform better, reducing lift-off over time.

Indoor vs. Outdoor? Completely Different Game

You wouldn’t wear a raincoat inside the office or bring a flip-flop to a snowstorm—same logic applies here. Indoor labels don’t need the same UV or weather resistance that outdoor environments demand. If your application calls for outdoor use, materials like UV-stable polyester and laminated vinyl are built to withstand sun exposure, rain, and fluctuating humidity. These resist fading and degradation longer, especially when paired with reflective technology for visibility in low-light conditions.

Temperature Extremes: Hot, Cold, and Everything Between

Manufacturing lines can get insanely hot. Freezers and outdoor storage can drop labels below freezing. Choose materials rated for their temperature range—some polyesters hold up to 300°F, while others become brittle in cold. Pay attention to both the service temperature (what it needs to endure after application) and the application temperature (the range the material needs to be during installation).

Chemical, Moisture, and UV Exposure Add Up Over Time

Work in a washdown-heavy plant or chemical lab? Then moisture resistance and solvent durability aren’t optional. Labels exposed to water, cleaning agents, oils, or corrosives need protective topcoats or lamination to prevent smudging or degradation. UV exposure is another slow killer—especially on outdoor labels, which should include UV inhibitors or lamination layers to prevent sun-bleaching and cracking.

If you're still unsure after considering these factors, don’t guess—get samples, test them in your environment, and confirm they’ll do the job. In the world of safety, the wrong label material isn’t just a mistake—it’s a liability.

Durable Safety Labels for Tough Environments

When you're working in manufacturing lines, logging yards, or loading docks—any place where machinery hums and people hustle—labels take a beating. It’s not enough for a safety warning to simply exist—it has to endure. That means staying readable after scrapes, exposure to grime, vibration, and constant handling. Throw in heat, cold, or strong solvents, and you’ve got a decent stress test. The real question is: what label materials are built to take that kind of punishment?

For environments where mechanical wear is expected, vinyl and polyester top the list. Vinyl's flexibility works well for irregular surfaces and tight curves, while polyester brings strength and stability, especially when laminated. Laminated polyester, in particular, resists abrasion, keeps ink sealed beneath the surface, and doesn't flinch at industrial cleaners. If the label gets touched often—think control panels or lift points—go with a material that's both scratch-resistant and chemical-resistant. You want your warning labels to outlast the shift, not disappear by the third equipment cycle.

Pressure-sensitive adhesives also matter. Standard adhesives might peel or slide, especially on textured, dirty, or oily surfaces. In these scenarios, high-tack industrial adhesives grip better and hold longer. The same goes for labels on rough construction gear and heavy equipment. No one has time to replace warning signs because of a weak stick—even less time to deal with the safety gaps that causes.

And don’t forget the signage that doubles as guidance in dimly lit areas. In those cases, integrating durable labels with reflective elements can mean the difference between noticeable and missed. For high-wear zones that still need to catch attention in low light, check out our reflective technology collection—built for both longevity and visibility.

Bottom line? If the gear moves, gets dirty, or works in extreme conditions, your safety labels should too. Choose materials engineered for impact, resistant to wear, and capable of holding fast even when the environment pushes back.

Weatherproof Hazard Signs: What Holds Up Outside

If your safety label is going to live outdoors, it better be tough. Wind, rain, sunlight, temperature shifts—they all work overtime to wear down weaker materials. That’s why it’s critical to understand what weatherproof really means—and how that’s different from just weather-resistant.

Weather-resistant materials can take a little rain or sun, maybe survive a drizzle or two before they start to wear. Weatherproof materials, though? They're built for battle. These are the decals that stay put and stay legible through scorching heatwaves, freezing winters, and sideways rain. In other words, the ones you’d actually want around in real-world outdoor conditions.

Materials That Last Outside

UV-stable polyesters and laminated vinyls are top picks when you need outdoor longevity. UV-stable polyester, for example, resists fading and cracking even with full sun exposure. It’s a go-to choice for industrial yards, construction zones, and places where heavy machinery throws off a range of environmental stressors.

Laminated sheeted vinyls add another layer of protection. The lamination acts like a weatherproof shell—guarding against abrasion, water intrusion, and good old-fashioned sun bleaching. This combo is perfect for warning signs or instructional labels that can’t afford to weaken just because the weather changed.

Considering outdoor visibility? Reflective materials, like those in our reflective technology collection, make labels pop in low-light or poor-weather conditions. Whether you're working around moving equipment at dusk or navigating a facility in the rain, reflective decals boost visibility without relying on ambient lighting.

Preventing Peeling and Water Damage

Because no label is useful if it peels off or turns into a soggy mess, smart adhesion matters just as much as the chosen material. Pressure-sensitive adhesives, often paired with durable backings, create bonds that last even when humidity spikes or surfaces flex with temperature shifts.

Also, don't overlook corners and edges—these are the most vulnerable to curl and peel if not sealed properly. A clean, dry, prepped surface plus the right label design can make the difference between a label that sticks for years and one that fails next season.

Long story short? Outdoor labels need armor. Choose the material that matches your environment, make visibility a priority, and don’t skimp on adhesive performance. That’s how you keep safety communication standing strong—storm after storm.

Chemical-Resistant Decals: Protection Against Harsh Substances

When your work environment includes acids, oils, fuels, solvents—or anything that comes with a Material Safety Data Sheet—you need labels that won’t dissolve, fade, or peel after a few cleanings. In settings like chemical plants, manufacturing floors, labs, or maintenance areas, decals are often exposed to substances that can obliterate standard adhesives or ink in a matter of hours.

This isn’t a minor issue. Label failure in these environments could mean undetected hazards or misidentified materials. That’s a surefire way to invite injury—or a compliance audit.

Go with materials built to fight back. Laminated polyester is a top performer here. It resists abrasion and most cleaning agents, especially when combined with a high-bond adhesive. Want something even tougher? Anodized aluminum offers subsurface printed graphics, meaning the label information is sealed beneath a protective layer of aluminum oxide. Your message stays visible—even if the surface gets scuffed, soaked, or saturated in solvents.

Keep in mind—labels in chemically harsh environments also tend to be cleaned frequently. That means pressure washing, wiping with solvents, or being sprayed down at the end of a shift. These conditions demand adhesives that stay put. Pressure-sensitive adhesives, paired with surface preps like degreasing, help labels grip even when applied to slick or porous surfaces.

If clarity after chemical exposure is non-negotiable—especially in low-light or high-risk areas—consider using reflective materials for added visibility. For example, our reflective technology decals pair toughness with brightness, ideal when the message needs to shine through grime, wear, or poor lighting.

Bottom line? In environments where harsh substances are par for the course, not just any label will do. Pick a material designed for the chemical battle—and make sure it’s engineered to win.

High-Visibility Labels: When Clarity Saves Time

In fast-paced or high-risk environments, speed isn't a luxury—it's survival. Whether you're navigating a dim factory floor, responding to an emergency, or scanning equipment during a routine check, high-visibility safety labels cut through noise and chaos. Visibility isn't just about color; it's about clarity when seconds matter.

Bright Colors, Bold Choices

Colors make the first impression. Standard safety label guidelines push for specific shades—fire red, caution yellow, safety green—for a reason: they trigger recognition. But beyond color psychology, you’ve also got to consider saturation and finish. Glossy finishes can reflect overhead lights causing glare, while mattes or satin coatings reduce reflections for better legibility, especially under harsh lighting.

Contrast Is King

A label can have the right color scheme and still fail if the contrast isn’t strong enough. Black text on a yellow background? Easy to read. Light gray on white? Hard pass. A clean font in high contrast does more than look good—it prevents mistakes. And while we're at it, don’t skimp on font size. Labels stuck on high equipment or behind barriers aren’t helpful if they’re microscopic.

Reflective Materials for Low-Light Conditions

Some work sites never see daylight—parking garages, mines, or overnight operations all bring visibility challenges. In those cases, reflective decal technology becomes essential, bouncing light back to the source for high legibility even in minimal lighting. Need a breakdown of which materials are designed to catch a beam from a flashlight or vehicle headlight? Check out our reflective technology collection for options that don’t quit once the sun sets.

Emergency Response Situations

In urgent situations like fires, spills, or machinery faults, no one has time to squint. Here’s where high-visibility labels do heavy lifting—guiding workers toward exits, valves, shut-offs, or hazard zones. Quick glances become reliable decisions. The right label acts like a silent assistant, cutting confusion when it matters most. For maximum visibility in these moments, mounting angle and placement are just as important. If you're unsure how to optimize that setup, our hardware collection for mounting options can help you get it right.

Bottom line: you don’t just need your labels to be visible—you need them to stand out instantly. High-visibility safety labels are more than just bright—they're designed to operate like visual alarms. Choose wisely, and they’ll deliver when you need them most.

Common Questions About Industrial Safety Label Materials

Choosing the right material for your safety labels can feel like solving a moving puzzle—especially when the risks aren't just hypothetical. Below are some of the most common questions we get from customers trying to make the right call in real-world conditions.

What’s the most durable label material available?

Anodized aluminum takes the crown for long-term durability. It's physically tough, corrosion-resistant, and the graphics are sealed beneath the anodic layer—meaning they won't scratch, fade, or peel under normal use. It's ideal for harsh industrial settings, especially when exposed to abrasion or UV light. Laminated polyester is a close second, especially when chemical resistance and legibility under wear are priorities.

How do I know if my labels are compliant with safety regulations?

Compliance isn't just about sticking a red and white label on something and calling it a day. OSHA, ANSI, and ISO have stringent guidelines outlining label size, color coding, signal words, and placement. The best way to stay compliant is to match label material and design with the specific standard that applies to your facility. If you're unsure, working with a vendor who understands safety labeling rules is a smart move.

Can safety labels be applied to oily or rough surfaces?

Yes—but surface prep is everything. No label will stick permanently to an oil-slicked panel or a flaking concrete wall. The surface needs to be clean, dry, and as smooth as possible. That said, pressure-sensitive adhesives used on some high-performance labels (especially on vinyl or polyester backers) can grip textured or curved surfaces better than standard adhesives. For extra-rough areas, we offer mounting hardware options that keep signs in place when adhesive alone isn’t enough.

How long do chemical-resistant decals last?

It depends on the specific chemicals and how often the surface is cleaned, but high-quality laminated polyester or anodized aluminum decals can last anywhere from 5 to 10 years in chemical-rich environments. Labels exposed to regular washdowns with solvents need both a tough face material and a chemical-resistant adhesive. Pay attention to product specs, and don’t cut corners on lamination—it’s not just a shiny finish, it’s a protective barrier.

Which material works best outdoors in extreme weather?

UV-stable polyesters and laminated vinyls are your best bet for battling sun, rain, snow, and temperature swings. These materials are designed to resist fading from UV exposure and won’t crack or curl when the weather turns nasty. For maximum visibility in low-light or fog, consider labels that use reflective safety technology, which keeps visual cues clear even when sunlight isn’t on your side.

Still have questions? Choosing the wrong material can cost more in reprints—and compliance issues—than getting it right up front. When in doubt, ask.

Application and Maintenance Tips

Even the toughest label won't do its job if it's slapped on a dirty, uneven surface or installed like an afterthought. Application and maintenance matter just as much as material choice. Here's how to get it right from the start—and keep your safety labels doing their job long-term.

Prep Like It Matters—Because It Does

Before you apply anything, clean the surface. And not just a quick dust-off. Use a proper degreaser or alcohol-based cleaner to remove grime, oil, or any residue. Labels don’t stick well to damp, dirty, or textured spots. For oily environments like machine shops or kitchens, make sure surfaces are not just wiped but fully degreased.

Application Techniques (No, It’s Not Just “Peel and Stick”)

Most industrial safety labels use pressure-sensitive adhesives. Great—until they bubble, crease, or stick slightly off-kilter. To reduce bubbles or misalignment, use a rigid squeegee or roller during installation. For larger decals, start from one edge and work outward slowly, pressing as you go. If your labels need to be mounted instead of applied directly to equipment or rough masonry, consider using appropriate mounting hardware to get a secure fit.

Basic Maintenance Goes a Long Way

Once your labels are in place, don’t forget about them. Regular wipe-downs—particularly in dusty or process-heavy environments—stop dirt from dulling high-visibility surfaces. For labels exposed to sunlight, cleaning can also help prevent UV damage from accelerating wear. If you chose laminated finishes or outdoor-grade vinyls, these checks will help extend lifespan even more.

Know When to Replace

Faded, curling, or cracked labels lose more than just looks—they lose effectiveness. Develop an inspection routine to regularly check label condition throughout your facility. Replace any label that’s faded, unreadable, or damaged. Don’t wait for a safety audit (or worse, an accident) to find out your labels aren’t doing their job.

A great label isn’t just made of rugged material—it stays readable and in place because someone took five extra minutes to apply and maintain it right. Don’t skip that part. It's small effort, big payoff.

Regulatory Considerations and Standards

Choosing a label material isn’t just about durability—it’s about compliance. Industrial safety labels are tightly regulated by organizations like OSHA (Occupational Safety and Health Administration), ANSI (American National Standards Institute), and ISO (International Organization for Standardization). These standards shape everything from label color and wording to placement and font size. Mess these up, and you could be looking at more than operational confusion—you could face hefty fines or safety violations.

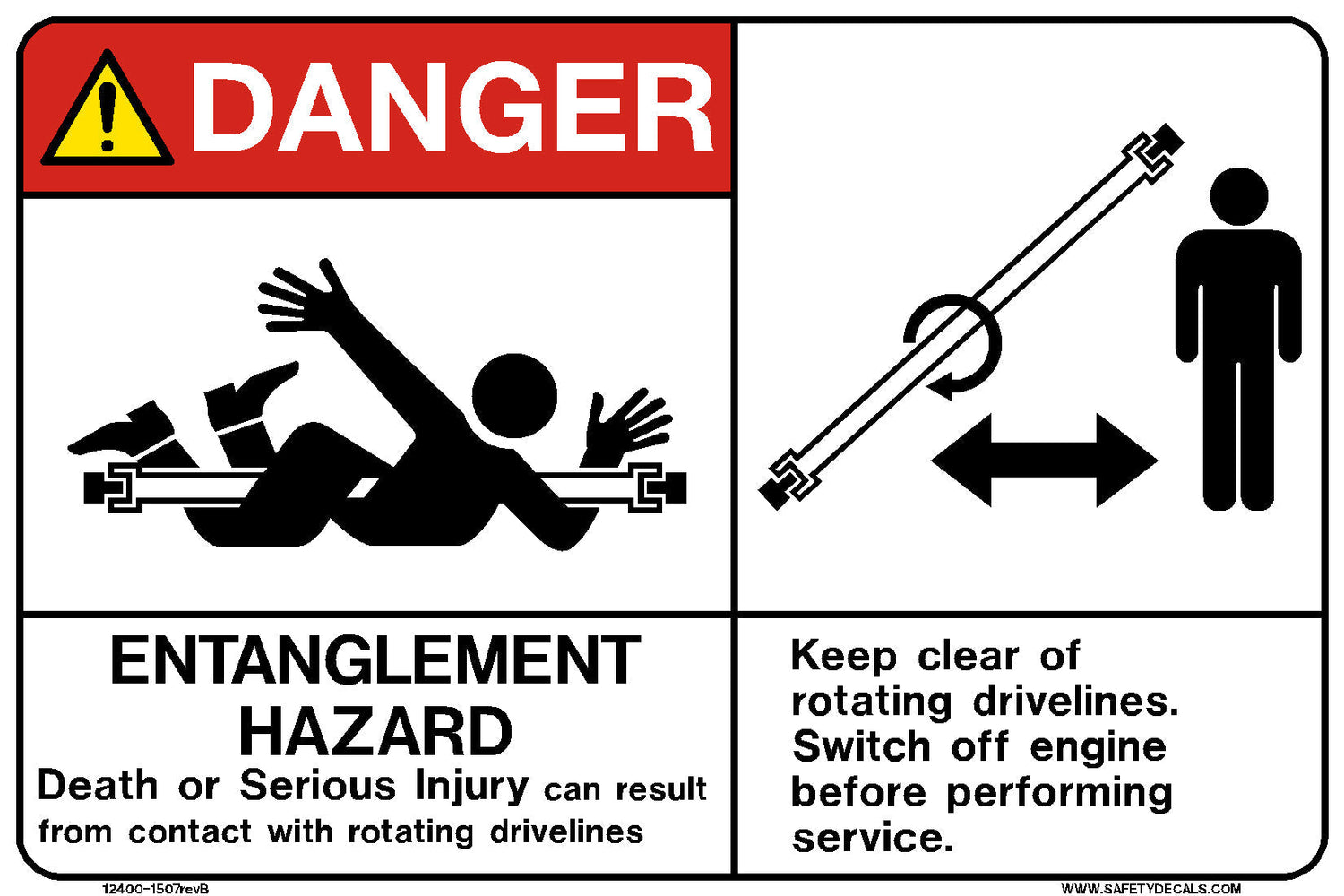

Color codes and signal words aren’t optional—they're legally driven. For example, OSHA requires that specific signal words like Danger, Warning, and Caution match certain hazard levels. These need to be printed in designated colors (such as red for Danger) to properly communicate risk. The label material has to support these high-contrast requirements, especially if it's being placed in areas where visibility is compromised.

ANSI Z535 standards take it further, addressing layout, symbols, and legibility. A faded or illegible label isn’t just ineffective—it’s non-compliant. If your label will be exposed to dirt, abrasion, or chemical splash, it’s smart to go with something like laminated polyester or subsurface-printed vinyl to prevent key information from wearing off. If you’re using reflectivity for emergency signage, make sure the material also aligns with ANSI’s retroreflective guidelines—our reflective technology collection is built specifically with visibility and compliance in mind.

Documentation is another piece that often gets overlooked. Keeping records of where and when labels are applied, their materials, and their specific compliance references can ease inspection stress. Regulatory bodies don’t just want to see the label—they want to know it was applied properly and inspected regularly.

Remember, safety labels are a legal tool as much as a visual one. It’s not enough that they stick well—they must also stand up to scrutiny. Always cross-check your materials with the standards relevant to your industry, and if you're mounting signs in tricky areas, our hardware collection offers rugged options to keep everything secure and in line with regulation.

Conclusion

Choosing the right material for your industrial safety labels isn’t just about longevity—it’s about responsibility. The wrong label can fade in the sun, disintegrate under chemical exposure, or peel off when it’s needed most. That’s a recipe for confusion, non-compliance, or worse—injury.

The right material, on the other hand, stays put. It stays readable. It works quietly in the background while people focus on the task at hand. Whether you're labeling corrosive pipelines in a chemical plant or marking exits in a low-light warehouse, the right choice balances durability, visibility, and environmental resistance.

Make it a habit to check your safety labels periodically. Are they cracked? Faded? Peeling at the corners? Replace them before they become a liability. Don’t wait for a failed inspection or a close call to realize a decal didn’t hold up.

And most importantly—match your materials to your environment. Outdoors? Go with something UV-stable and waterproof. Exposed to corrosives? You need chemical resistance. If visibility in dark or dynamic conditions is a factor, consider materials enhanced with reflective technology that help labels catch the eye, even when light is low.

Safety isn’t just about having labels—it’s about having the right ones, in the right places, made from the right stuff. Choose wisely.