The Difference Between ANSI and OSHA Safety Standards

Safety standards form the backbone of workplace protection, with ANSI and OSHA playing distinct yet complementary roles in ensuring employee safety. Understanding these differences is crucial for maintaining compliance and creating a safer work environment.

What Are Safety Standards?

Safety standards serve as frameworks designed to identify and mitigate risks, prevent accidents, and promote employee well-being. They address everything from machinery operation to chemical handling, creating an environment where employees can work without worrying about preventable risks.

ANSI's Role

The American National Standards Institute (ANSI) operates as a private, non-profit organization that enhances workplace safety through voluntary guidelines. Think of ANSI as the architect of best practices, creating blueprints for safety that industries can choose to adopt.

Key Characteristics

- Develops consensus standards with industry experts

- Provides voluntary guidelines

- Creates comprehensive safety frameworks

- Focuses on optimal safety practices

OSHA's Authority

The Occupational Safety and Health Administration (OSHA) functions as a federal agency with legal authority to enforce workplace safety laws. Unlike ANSI's voluntary approach, OSHA's standards are mandatory, with violations resulting in fines and penalties.

Enforcement Powers

- Conducts workplace inspections

- Issues citations and penalties

- Sets legally binding regulations

- Ensures minimum safety requirements

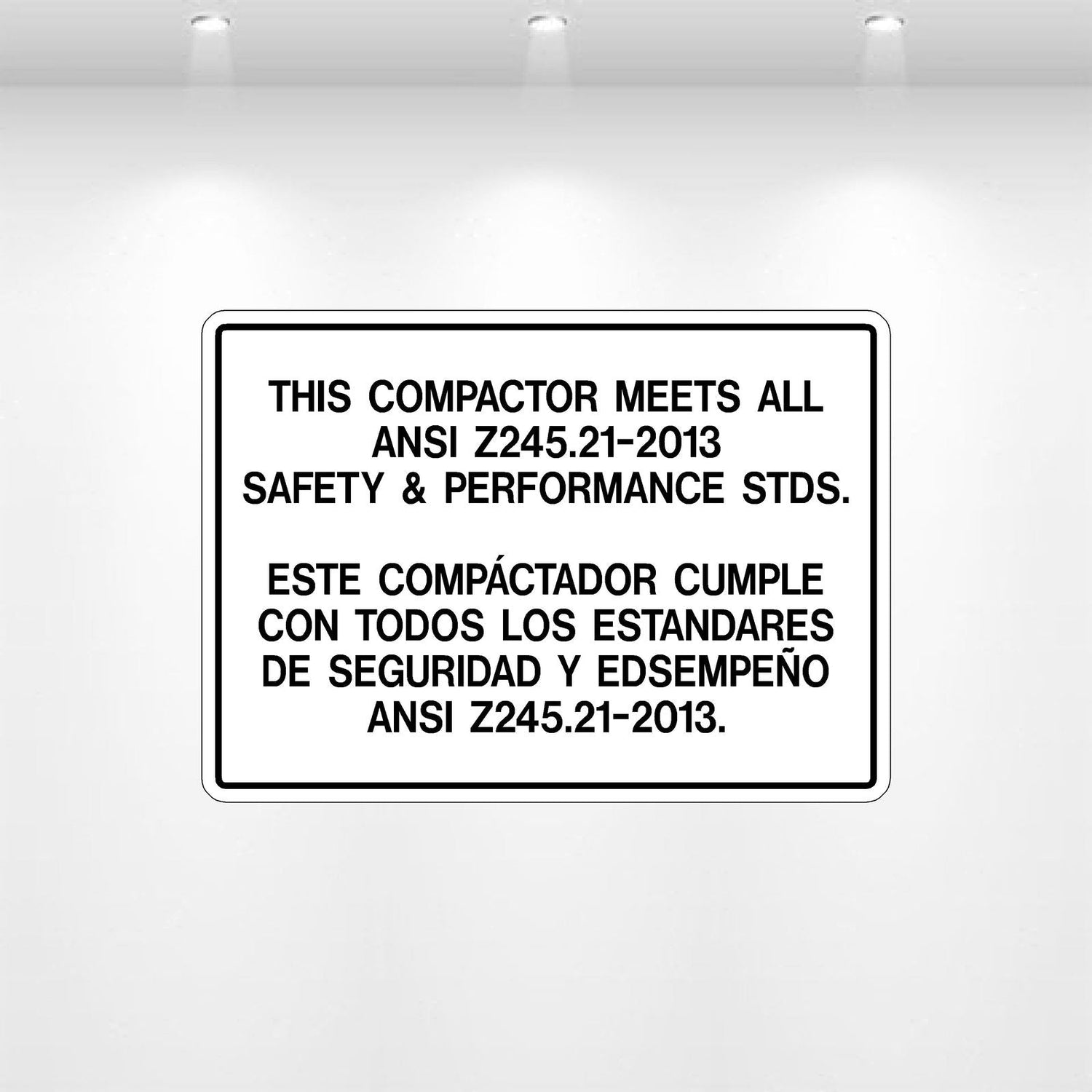

Label Requirements

Need to ensure your workplace meets both ANSI and OSHA standards? Browse our selection of hazard warning decals designed to meet compliance requirements.

ANSI Z535 Standards

ANSI's guidelines focus on clarity and consistency in safety communication. They specify:

- Signal words (Danger, Warning, Caution)

- Color coding (red for danger, orange for warning, yellow for caution)

- Standardized symbols and pictograms

OSHA Requirements

OSHA mandates specific elements for hazard communication:

- Product identifiers

- Hazard statements

- Precautionary measures

- Required pictograms

Best Practices

To learn more about implementing effective safety standards in your workplace, read our article on ANSI and OSHA safety standards.

Strategic Implementation

- Conduct regular risk assessments

- Train employees on safety protocols

- Update labels as needed

- Stay current with changing standards

- Integrate safety into company culture

Remember, effective safety communication isn't just about compliance—it's about preventing accidents before they happen. When ANSI's best practices and OSHA's requirements work together, everyone wins.