Safety is essential in every workplace, and clear communication about potential hazards can save lives. OSHA labels play a crucial role in keeping workers informed and protected. When properly designed, these labels reduce risks and help businesses comply with federal safety standards.

Understanding OSHA Labels

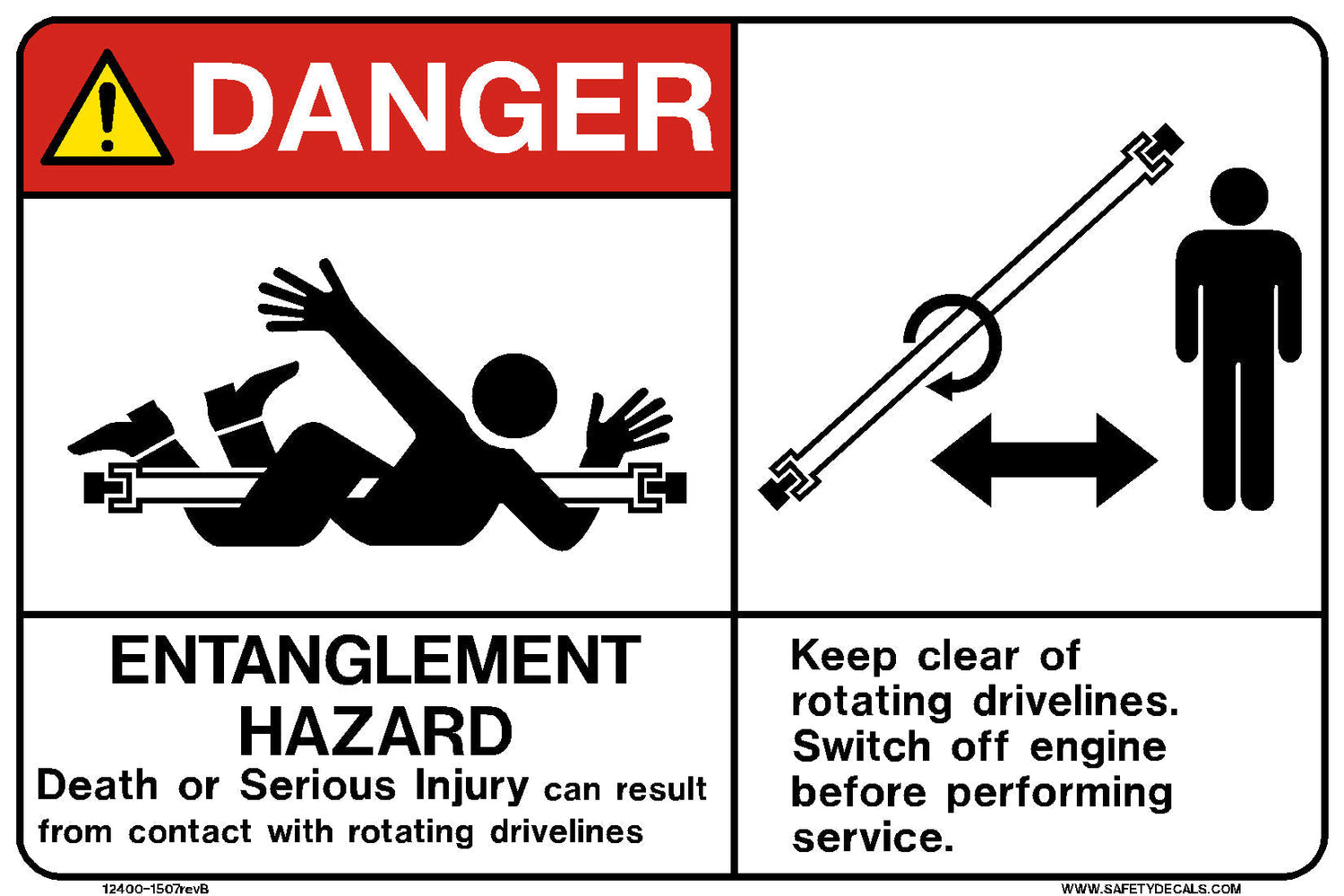

OSHA labels are much more than stickers with bold words and flashy colors—they're the frontline communicators of workplace safety. These labels identify hazards, outline precautionary steps, and ultimately protect workers from harm, acting as a bridge between potential dangers and safe operating practices.

Key Elements of Compliant Safety Decals

Every detail matters when designing safety decals that meet compliance standards. These aren't just stickers—they're often the first line of defense between a worker and a hazardous situation.

Signal Words and Colors

Clear signal words paired with specific colors create an instant visual language:

- Danger (Red) - For life-threatening risks

- Warning (Orange) - For serious hazards

- Caution (Yellow) - For less severe risks

Machine Safety Labels

For machinery and equipment, safety labeling requires special attention to both operators and maintenance personnel. Labels must communicate immediate visual cues while providing detailed instructions when necessary.

Material Selection and Durability

Premium materials like engineered vinyl or polyester provide essential resistance to fading, cracking, and peeling. UV-cured inks and thermal transfer printing ensure long-lasting visibility, while laminated finishes protect against harsh environmental conditions.

Strategic Implementation

The effectiveness of safety decals relies heavily on strategic positioning. They must be placed near operating controls, at access points, close to moving parts, and in clear sight without interfering with equipment operation.

Looking to enhance your workplace safety? Browse our selection of industrial-grade safety decals designed to meet OSHA standards and withstand demanding conditions.

Maintenance Requirements

Regular inspection ensures continued effectiveness. Perform quarterly checks for signs of peeling, fading, water infiltration, or physical damage. Replace compromised labels immediately to maintain continuous protection.

Impact on Workplace Safety

Properly implemented safety decals serve as silent sentinels, protecting workers while ensuring operational efficiency. They prevent accidents, foster a culture of safety awareness, ensure regulatory compliance, and bridge communication gaps in multilingual workplaces.